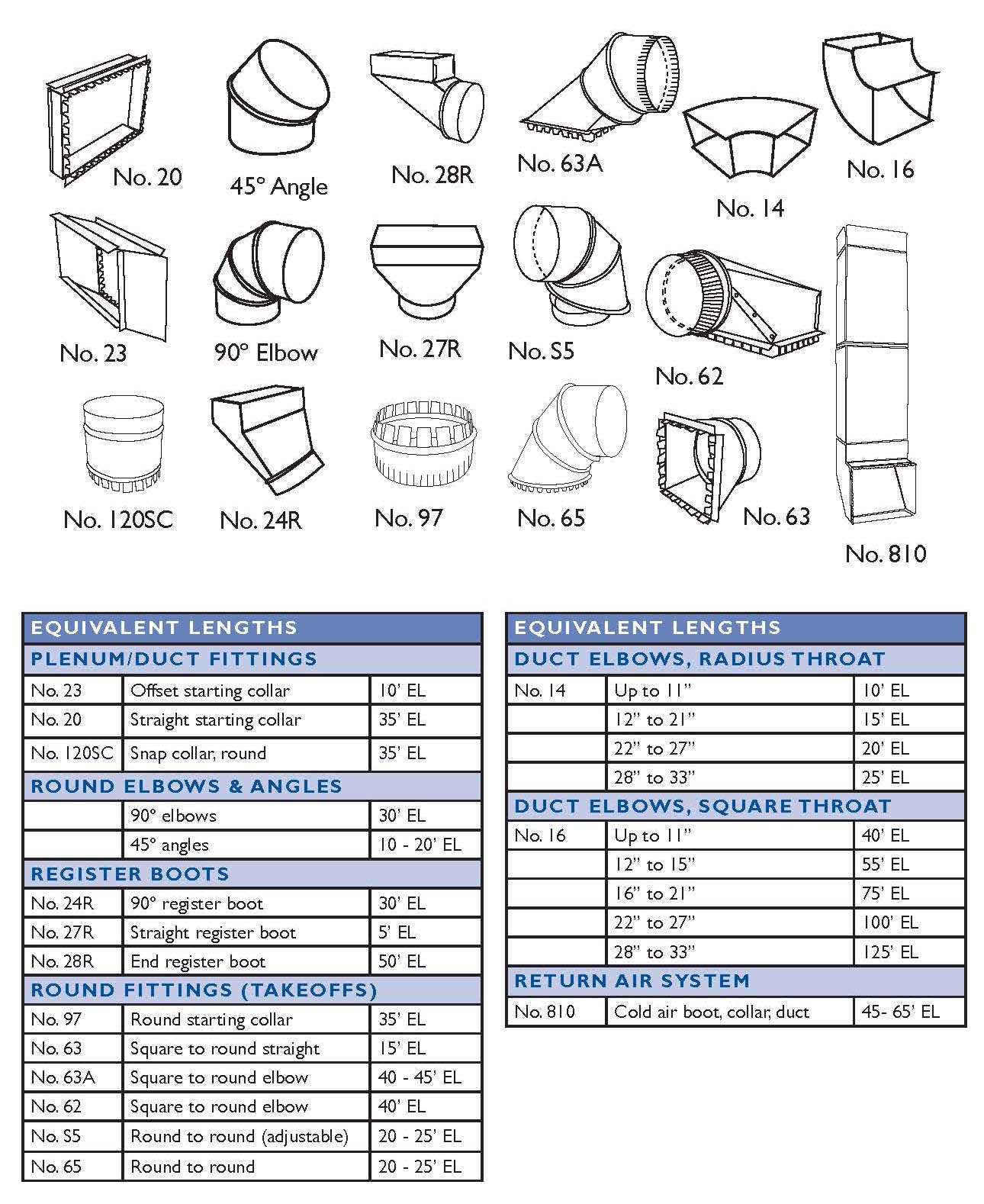

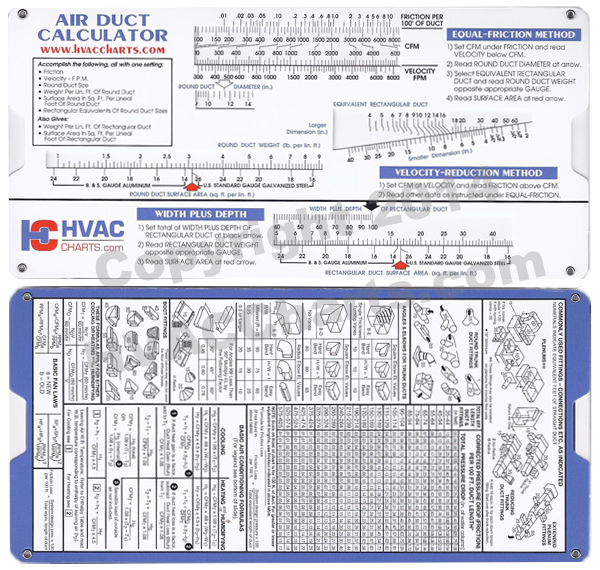

Back of calculator has equivalent feet of straight duct for commonly used fittings corrected pressure drop chart and many hvac formulas.

Hvac duct fittings equivalent length chart.

D e equivalent duct diameter inches.

This value is the comparison length of this fitting to an equivalent length of straight pipe or duct.

A 8 2 ashrae duct fitting database program.

This article details the calculation of pressure losses through pipe fittings and some minor equipment using the equivalent length method.

The strength of the equivalent length method is that it is very simple to calculate.

From table a 3 the equivalent round size is 9 4 inches.

δh 0 109136 q 1 9 d e 5 02 1.

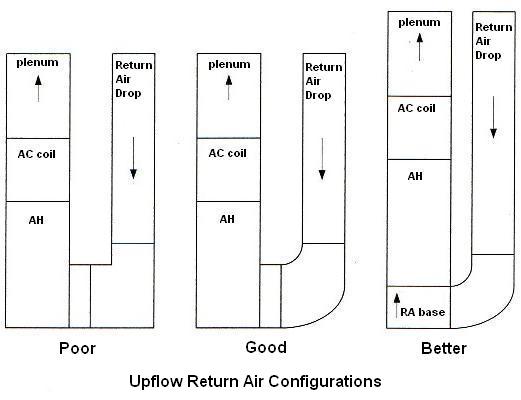

Energy vanguard this duct design shows the layout of a duct system including the fittings and duct sizes.

For example each elbow used is equivalent to 30 feet of straight pipe or duct.

Use the friction chart at 1000 cfm in 9 4 inch diameter to friction loss is 0 5 in water 100 ft.

A common duct pressure of 0 25 inches water column is equal to 0 25 divided by 27 7 in wc psi 0 009.

One method of duct design relies on calculating the total effective length which is the sum of all the lengths of the straight sections of duct and the equivalent lengths of the fittings.

Q air volume flow cfm cubic feet per minute.

12 x 7 flat oval 1000 cfm solution.

δh friction or head loss inches water gauge 100 ft of duct.

The photo shows front and back sides of the calculator.

For rectangular ducts the equivalent diameter must be calculated.

Fittings such as elbows tees and valves represent a significant component of the pressure loss in most pipe systems.

Equivalent duct sizes for same friction loss from.

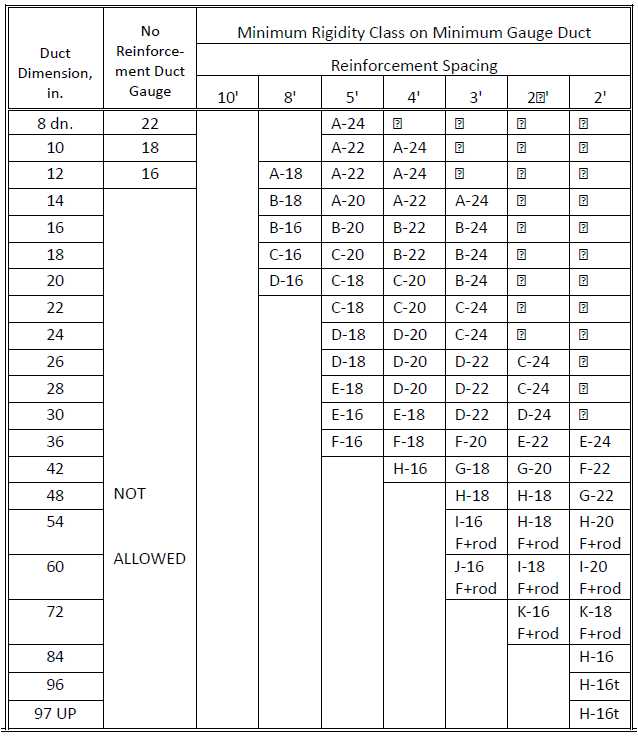

Pull out slide has recommended duct velocities recommended gauges for sheet metal and much more.

The weakness of the equivalent length method is that.

A 1 3 1 round duct size and area.

1 psi equals 27 7 inches of water gauge.

Each fitting has an effective length that equates its pressure drop to an equivalent amount of straight duct.

When you add up the effective lengths of all the fittings and then add that number to the length of the straight sections in the most restrictive runs in the return and supply ducts you find the total effective length tel.

The major loss or friction loss in a circular duct in galvanized steel with turbulent flow can for imperial units be expressed.